Materials

We provide a comprehensive range of material options to suit all environments and operating parameters.

Backing shells can be made using Copper or Chromium Alloys for

high operating temperatures & loads, due to their enhanced

heat dissipation properties, and increased structural strength.

Specially hardened, high carbon alloys are used for pivots

and levelling blocks to reduce wear, and provide maximum

stability.

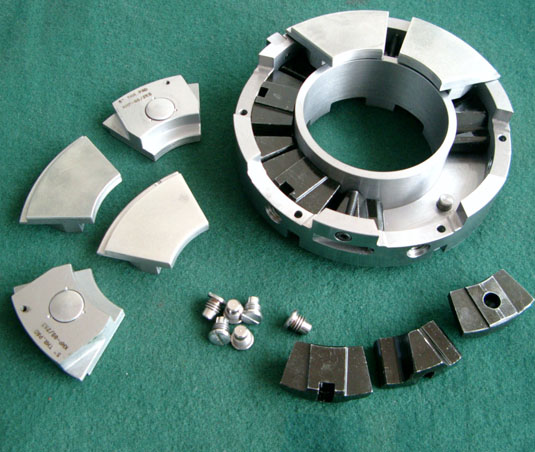

Part Description

Material

- Main Housing/Casing

- Cover Plate

- Base Plate

- High Alloyed Steel

- Runner

- Base Ring

- Alloy Steel

- Guide Bearing/Pad Backing Shell

- Thrust Pad Backing Shell

- Carbon Steel

- Copper Alloys

- Chromium Alloys

- Babbitt Lining

- ASTM B23 Gr II

- Tego Star (Ecka Granules, Germany)

- HOYT Alloys

- Pivot

- Alloy Steel - Hardened (50-60 HRC)

- Heat Exchangers

- Tubing - SS 304/316 or Cupro-Nickel

- Fins - Aluminium

- SS Connectors for Inlet/Outlet ports